Eco Flow Systems

Ecoflow

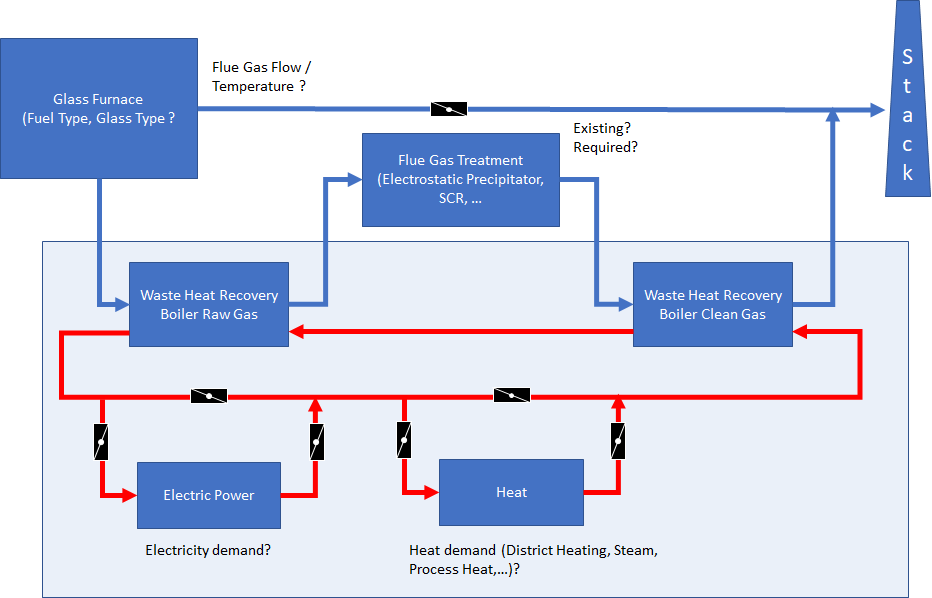

Heat recovery systems with:

- Heat duties from 100 to 50.000 kW

- Heat transfer fluid: preferred water or thermal oil

Glass Industry

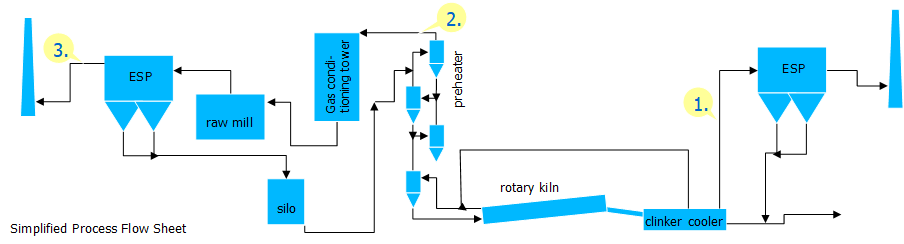

Cement Industry heat recovery for:

- Clinker cooling air

- Pre-heater waste gas (PH)

Waste gas before passing gas conditioning tower and electrostatic precipitator (ESP) or bag house (BH) - Waste gas

after passing electrostatic precipitator (ESP)

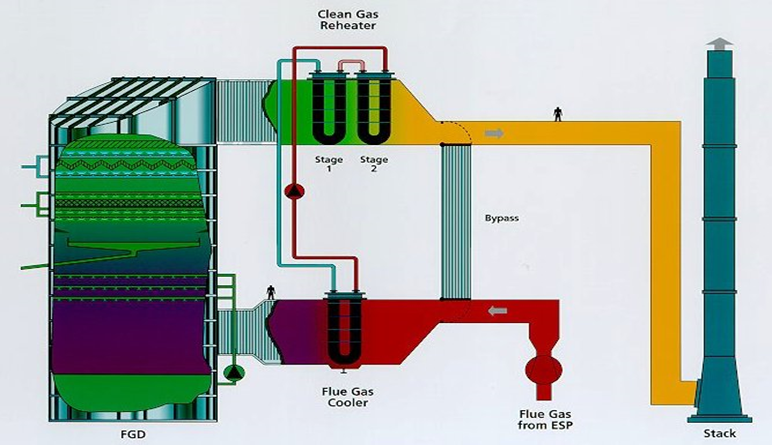

FGD Application

Gas compressor station

Heat recovery system including:

- Waste heat boiler

- Water treatment plant

- Turbine & generator

- Air condenser

- Process control system

Combined Steam and Power Generation 16 MWel, netto

Waste Gas 390.000 Nm³/h; 569°C;

Steam 72 t/h, 480°C

Key Advantages

- Simple heat exchange technology

- Surmountable large distances between heat source and consumer

- High operational flexibility for any consumer

- Adaptable to the requirements of the consumer

- Opportunity for CHP with steam turbine or ORC

- High control ability

Services

- Engineering and delivery

Referenzen

alle Referenzen

CSC - China Steel Corporation

ECOFLOW for the preheating of fuel gas and combustion air at the heater from hot blast furnace exhaust

weiterlesen

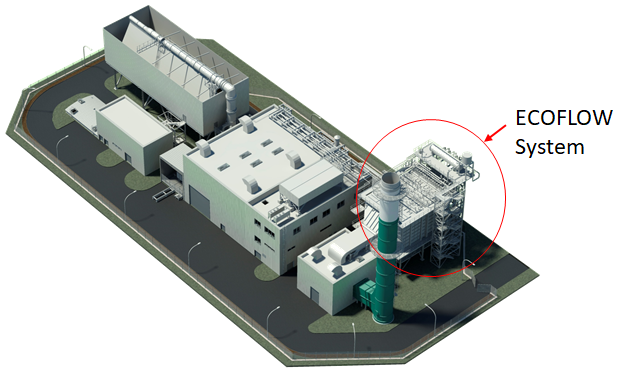

OMV Weitendorf

ECOFLOW for steam generation with subsequent generation of electricity from the exhaust gases of gas turbines

weiterlesenThe strengths of Küttner

Electric and Automation

New production processes and flexible process technology are placing ever increasing demands on elec…

Read more

Digital Operations

The fourth industrial revolution is a reality. The real and virtual worlds are moving closer togethe…

Read more

EPC-Contracting

Whether you are planning a new production plant or want to modernize your existing equipment: It is …

Read more