Turnkey competence in new constructions and modernizations

Metallurgy - Process engineering - Construction - Electrical engineering - Automation - Project management

Together we develop your customized solution. Our in-house, wide-ranging technical expertise, combined with our many years of implementation experience, will provide you with the solution that best suits your needs. We work with you to find the optimum balance between technology, costs, implementation times and downtimes.

References in numbers

A wide range of experience from countless new construction and modernization projects is ready for your challenges. Our claim for all solutions: minimal downtimes and steep ramp-up curves.

-

#1Worlds first H2 injection

-

2.500.000 m3/hGreatest sintering gas cleaning

-

> 20.000 I/OSimulation at VOEST (A)

-

100Blast furnace burdening

-

80Alloying systems

-

30Ladle treatment stands

Raw materials

In this area, we summarize our activities relating to conveying and processing technology for metallurgical feedstocks, products and by-products. In addition to classical plant construction, this also includes process consulting, which includes e.g. in connection with the sintering laboratory equipment and on the coking plant.

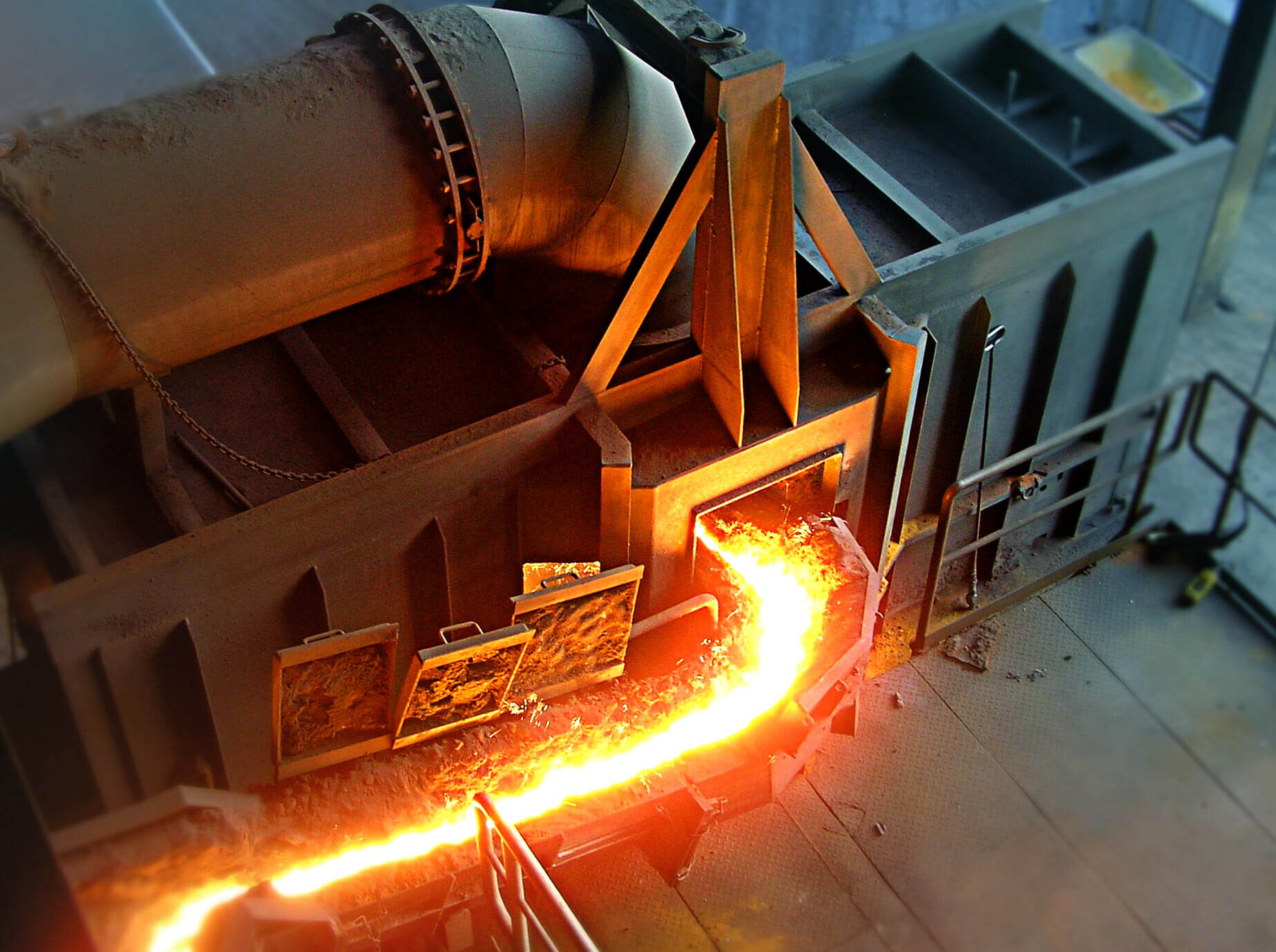

Hot metal/Steel

Küttner is an established supplier in the iron and steel industry and has well-founded operator know-how for large blast furnaces, which repeatedly makes a significant contribution to the final concept finding. An interesting new field of activity was opened up by the construction of gout closures and large fittings.

Energy & Environment

As a result of the changed political discussion in Europe today, but also in the rest of the world, there are manifold requirements for operational environmental protection with ever stricter requirements for process gas purification, the detection and purification of fugitive emissions and the reduction of primary energy consumption. Küttner specializes in this field of environmental protection. In addition, the OXYCUP shaft furnace process was developed in the sense of the zero waste metallurgical plant.

Flexible installation with high expertise

In order to meet the challenges in metallurgical plant engineering, we have both specialized teams with high technological competence in the fields of metallurgy, power engineering, and automation technology; as well as experienced execution teams from the areas of project management, design, electrical, manufacturing supervision, and site management to both smaller and bigger companies to handle larger projects in an orderly manner.

References

HM De-S, Re-C, Re-Si at Tronox KZN Sands

HM De-S, Re-C, Re-Si at Tronox KZN Sands – Empangeni (RSA)

Learn more >The strengths of Küttner

Engineering

The basis of good planning is the clarification of facts and boundary conditions. This includes the …

Read more

Digital Operations

The fourth industrial revolution is a reality. The real and virtual worlds are moving closer togethe…

Read more

Electric and Automation

New production processes and flexible process technology are placing ever increasing demands on elec…

Read more