Joint process and solution development until final realization

State-of-the-art technology, Simulation, Holistic Solutions, Tailor Made

Together with our customers, we develop the project processes and plan possible plant configurations. Our interdisciplinary teams help with this: For example, specialists from the fields of metallurgy, process engineering, mechanical engineering, electrical engineering and plant engineering bring their respective know-how into the cooperation.

Based on the tailor made metallurgical process plants, the overall system configuration with material and raw material logistics, exhaust gas management system and product logistics is developed individually with the customer, and with technology and cost transparency. For the realization, we are then available to the customer as an EPC supplier: both with our own state-of-the-art technologies and also with customer technologies. Thus, the responsibility for appointments and budgets always remains in one hand right from the start. If desired, we also support our clients in finding suitable partners for financing.

Holistic competence

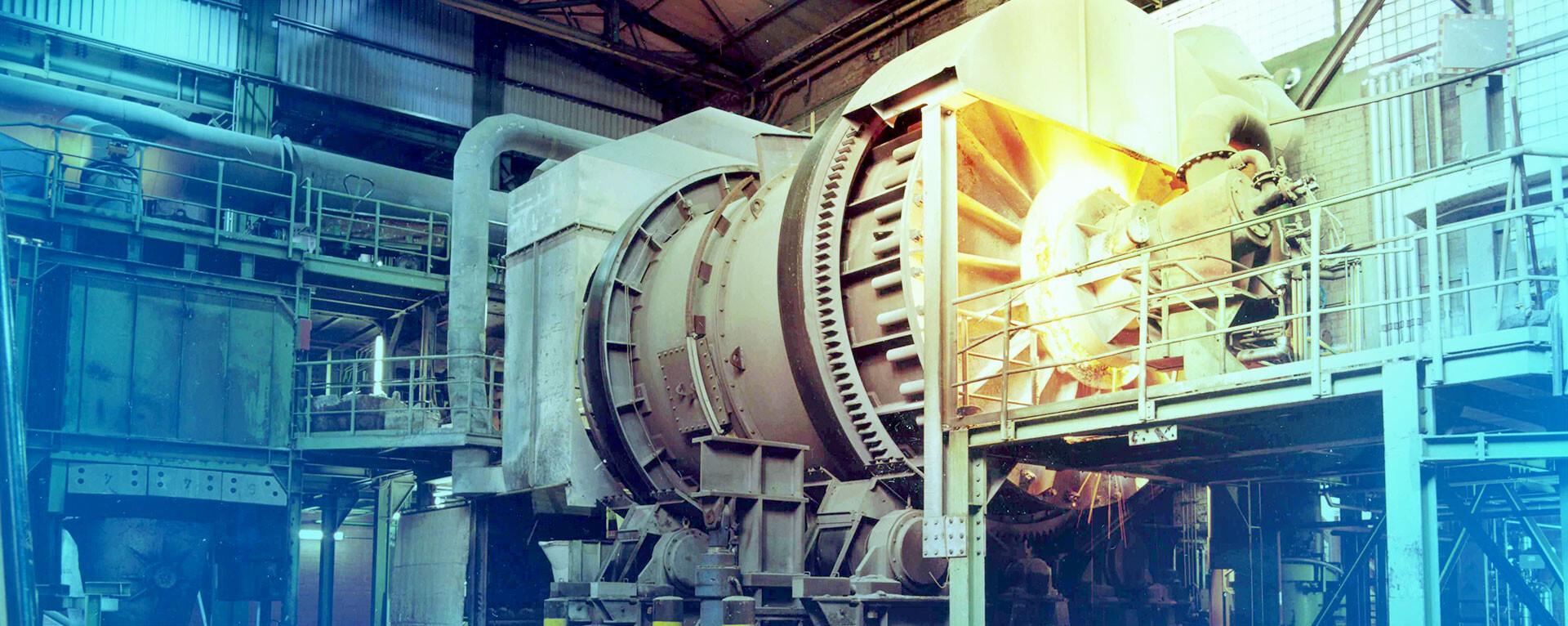

Non-ferrous metallurgy offers a diverse and exciting field of activity in plant engineering, especially in recycling. Nowhere else are the processes so individual, the raw materials so special, and the technical solutions so unique.

Partnership developed solutions are our passion. Our work is characterized by the close and trusting cooperation with our customers. We think outside the box and use our many years of expertise in the ferrous and energy industry to create individual systems for the non-ferrous industry with our interdisciplinary team.

-

#1First SBF lead slag reduction plant in Europe at Weser-Metall Germany (D)

-

#1Brownfield integration projects parallel to running operations

-

#1Excellence in tailor-designed complex projects development

-

> 99,9%Precious metals refining efficiency at BERZELIUS Stolberg GmbH (D)

-

0,2 mg/Nm³Mercury Separation - Optimization of 20 mg/Nm³ at Purified Metal Company (NL)

Raw materials

In the non-ferrous industry, the raw materials are extremely complex - especially in recycling, but also in the concentrates of primary raw materials. We are happy to face the challenges of processes, plant and exhaust gas technology as well as plant configuration: with non-ferrous metallurgical plants, which we design and implement as process-oriented unique pieces.

Non-Ferrous metallurgy

The planning and construction of facilities for the recovery and recovery of valuable metals are our passion. For example, we offer our customers reliable solutions for base metals such as lead, copper or zinc as well as special or precious metals such as silver, gold or platinum group metals.

Technologies

In plant engineering, we always look at the whole. Therefore, our customers not only benefit from technologies for processing metallurgical primary and secondary raw materials for the large number of industrial furnaces and various process stages. As the feedstock becomes increasingly complex, technologies for exhaust gas treatment and waste gas purification play an equally important role today - also to meet the stringent legal requirements for the protection of people and the environment.

Flexible installation with high expertise

In order to meet the challenges of metallurgical plant engineering, we have both specialized teams with high technological competence in the fields of metallurgy, energy and automation technology; as well as experienced project realization teams from the areas of project management, design, electrical, expediting and site management, to handle smaller and larger projects in an orderly manner.

References

The strengths of Küttner

Electric and Automation

New production processes and flexible process technology are placing ever increasing demands on elec…

Read more

Digital Operations

The fourth industrial revolution is a reality. The real and virtual worlds are moving closer togethe…

Read more

EPC-Contracting

Whether you are planning a new production plant or want to modernize your existing equipment: It is …

Read more